The Importance of Gaskets and Fittings in Key Steps of Craft Brewing

15th Apr 2024

Craft brewing beer involves many key steps, and know-how, all contributing to the final product's flavor, aroma, and quality. The equipment, tanks, gaskets, and fittings used in the brewing process also play an important role in ensuring the quality, consistency, and purity of the final product. Manway doors and gaskets allow for tank access for adding product, cleaning, and maintenance while tri clamp gaskets, fittings, and valves ensure a sanitary, efficient, and leak free operation. Below we offer an informative overview of the brewing process while highlighting key components, gaskets and fittings and how they often integrate into each stage.

Step: Mashing

Mashing involves mixing milled grains with hot water in a mash tun, a process that looks quite similar to making porridge. This step is crucial as it methodically heats the mixture, allowing the starches in the grains to break down and convert into fermentable sugars. The resulting thick mixture, known as the mash, contains malt sugars that will feed the yeast during fermentation.

Mash tuns are equipped with manway doors which allow brewers to access the interior for cleaning out spent grains, performing maintenance, and occasionally for adding grains and other adjuncts during the mashing process. The manway doors include a manway gasket which is important to ensure a tight seal, maintain sanitary conditions and prevent leaks. Manway gaskets should be regularly inspected for wear and damage, cleaned thoroughly after each use, and replaced as needed to ensure a reliable, sanitary seal.

Brewery Gaskets is a trusted source for these manway gasket replacements.

Mash tun vessels also include tri clamp fittings and gaskets which provide secure, leak-proof connections for piping water and transferring the mash. Butterfly valves can also be used to control the flow rate and sight glasses to monitor the flow and consistency of the mash mixture.

Step: Lautering

Lautering is a process of separating the mash into a clear sugary liquid called wort and spent grain. The separation is done using either a lauter tun or a mash filter. Usually, the sweet wort is run off first. The remaining substance is recirculated before sparging. During sparging, the extract that remains with the residual grains is rinsed off with hot water.

A lauter tun is a tank with a false bottom that allows the liquid wort to drain away from the spent grain husks while sparging. Lauter tun manway doors provide access for cleaning out grain husks and maintnence. A manway gasket is used to maintain the seal on the lauter tun manway door.

Similar to the mash tun, lauter tun connections can include triclamp fittings and gaskets to ensure sanitary connections for wort transfer, butterfly valves to control the flow of wort and sight glasses to monitor the clarity and flow during lautering.

1-1/2" sightglass at BreweryGaskets.com

Step: Boiling, Whirlpooling, and Cooling

Boiling, whirlpooling, and cooling are crucial steps in the brewing process that occur sequentially to ensure the wort is prepared for fermentation. After lautering, the wort is transferred to a brew kettle for boiling. Boiling sterilizes the wort and allows for the addition of hops, which contribute bitterness, flavor, and aroma to the beer.

After boiling, the wort is whirlpooled to separate out the hop particles and other solids. This process clarifies the wort before it is cooled. Whirlpooling helps to collect accumulated dense solids, mainly hop matter and coagulated proteins, ensuring a clearer final product.

Cooling the wort is the final step in this sequence. The hot wort is rapidly cooled to a temperature suitable for fermentation using a heat exchanger, ensuring the yeast can be added without being killed by the heat.

Brew kettles, typically made of stainless steel, have manway doors to facilitate cleaning, inspection and to add ingredients such as hops, spices, and other flavorings during the boil phase. It is important to maintain the brew kettle manway gasket to ensure a tight seal to prevent leaks and contamination. Whilrlpooling can take place in a separate vessel or as an integrated whirlpool system in the brew kettle.

Boil kettles, whirlpool vessels, and heat exchangers will also typically require tri-clamp fittings and gaskets to establish secure, leak free, sanitary connections, butterfly valves to control flow and sightglass fittings to monitor clarity.

Step: Fermentation

The cooled wort is transferred to a fermentation vessel, and yeast is added. The yeast consumes the fermentable sugars, producing alcohol and carbon dioxide. This process can take several days to weeks, depending on the beer style. The kind of yeast used and the fermentation temperature will determine whether the final product is an ale or a lager beer.

Fermentation vessels can be conical fermenters, cylindrical fermenters, or open fermenters where the yeast is added, and primary fermentation occurs. These tanks are often equipped with cooling jackets to control temperature.

Conical fermenters often have side or top fermenter manway doors to allow for thorough cleaning, inspection, and maintenance. This is particularly important due to the buildup of yeast and other fermentation byproducts. During or after primary fermentation, additional ingredients like fruit, spices, dry hops, or other flavorings can also be added through the manway door. This is often referred to as secondary fermentation or dry hopping. Quality tank manway gaskets are crucial for sealing and fermentation conditions.

Fermentation vessel connections also include tri-clamp fittings and gaskets for transferring wort into fermentation vessels and butterfly valves for controlling wort into the fermenters and beer into further processing.

Step: Filtration and Conditioning

After primary fermentation, the beer is chilled and allowed to settle. Filtration and the period of settlement depend on the beer style. Filtering is meant to stabilize the beer’s flavor, but not all beers undergo filtering. The beer is then conditioned, which can occur in the same vessel or a secondary one. During conditioning, the flavors mature, and any unwanted compounds can dissipate.

Bright Tank are vessels where the beer is conditioned, carbonated, and clarified before packaging. They can also used for secondary fermentation if needed. Bright tank manway doors typically feature a side manway for access to the tank’s interior for cleaning, carbonation stone maintenance, and inspection. Although less common, additional flavorings or carbonation agents can be added to the beer before packaging. Maintaining the bright tank manway gasket is essential to prevent leaks, ensure sanitation, manage pressure, and guarantee the safety and quality of the beer.

Bright tank connections also include triclamp fittings and gaskets as well as butterfly valves to regulate the flow during filtration and conditioning and sightglasses to monitor quality and flow.

After primary fermentation, the beer is chilled and allowed to settle. Filtration and the period of settlement depend on the beer style. Filtering is meant to stabilize the beer’s flavor, but not all beers undergo filtering. The beer is then conditioned, which can occur in the same vessel or a secondary one. During conditioning, the flavors mature, and any unwanted compounds can dissipate.

Bright Tank are vessels where the beer is conditioned, carbonated, and clarified before packaging. They can also used for secondary fermentation if needed. Bright tank manway doors typically feature a side manway for access to the tank’s interior for cleaning, carbonation stone maintenance, and inspection. Although less common, additional flavorings or carbonation agents can be added to the beer before packaging. Maintaining the bright tank manway gasket is essential to prevent leaks, ensure sanitation, manage pressure, and guarantee the safety and quality of the beer.

Bright tank connections also include triclamp fittings and gaskets as well as butterfly valves to regulate the flow during filtration and conditioning and sightglasses to monitor quality and flow.

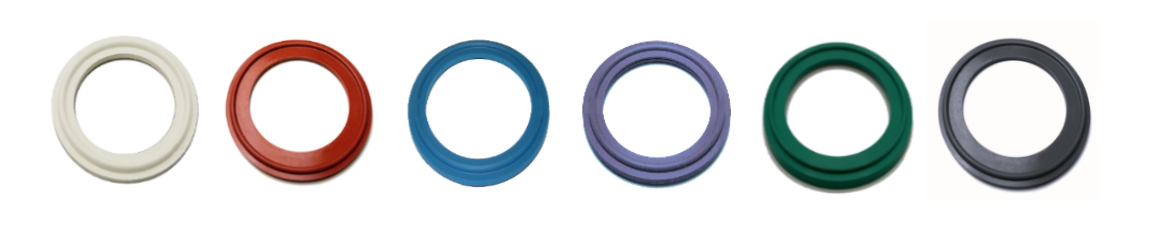

Large Selection of Tri Clamp Gaskets at BreweryGaskets.com

The craft brewing process relies heavily on the integrity and functionality of various equipment, tanks, gaskets, and fittings to ensure a high-quality final product. Proper maintenance and replacement of manway gaskets, tri-clamp fittings, butterfly valves, and sight glasses is essential to maintain sanitary conditions, prevent leaks, and ensure efficient operation at every stage of brewing.

For more information and for all your brewery gasket and fitting needs, visit BreweryGaskets.com and order online with fast, free shipping. Cheers to perfect brewing !

For more information and for all your brewery gasket and fitting needs, visit BreweryGaskets.com and order online with fast, free shipping. Cheers to perfect brewing !

About BreweryGaskets.com

BreweryGaskets.com has been a partner in the brewing industry since 2005, offering a wide range of gaskets, sealing products and fittings designed to meet the unique needs of breweries and beverage production. Our expertise lies in providing the right part for your operation to ensure dependable, leak free production. We offer durable, affordable gaskets and fittings including Tri-Clamp Gaskets, Manway Gaskets, Butterfly Valves and Seats, Tri Clamp Fittings and more. Our commitment to quality and customer-driven product inventory has made us a go-to source for brewers looking to maintain the highest standards in their brewing operations. Visit us and order online at BreweryGaskets.com.